Login or create an account

CloseReturning Customer

I am a returning customer

Login or create an account

CloseRegister Account

If you already have an account with us, please login at the login form.

Your Account Has Been Created!

Thank you for registering with SPARKTECH!

You will be notified by e-mail once your account has been activated by the store owner.

If you have ANY questions about the operation of this online shop, please contact the store owner.

Account Logout

You have been logged off your account. It is now safe to leave the computer.

Your shopping cart has been saved, the items inside it will be restored whenever you log back into your account.

Vegetable Oil Refinery

A refining process is carried out following extraction of crude edible oils by means of screw presses and/or solvent extraction.

In refining, physical and chemical processes are combined to remove undesirable natural as well as enviornmental-related components from the crude oil.

These components comprise for example phosphatides free fatty as acide( such as chlorophyll ) odors and flavors (including aliphatic aldehyde and ketone) waxes as well as heavy metals pesticides etc.

Depending on the requirements the following basic processes are implemented:

- Degumming for removal phosphatides

- neutralization for removal of three fatty acids

- beaching for removal of color

- deodoration to distll odors and flavors as well as three fatty acids and.

- winterization for separation of waxes

Refined edible oils are the directly used for human nutrition or serve further processing for example for mayonnaise margarine shortening and for the production of biodiesel Important process steps in this context are fractionation hardening and interesterification

Sparktech offers customized machine solutions for any application ar process to meet the individual requirement of the customers

Different degumming prooesses, are carried out to remove phosphatides .For efficient and economic application of this procedure.

SPARKTECH provides appropriate machines and equipments.

Water degumming

A large part of the phosphatides (gums) cab be hydrated quickty and easily. If the pressed or extracted oil contains a considerable quantity of gums the oil is subjected to the water decumming process immediately following extraction. In this process, Water added to the oil. Arter a certain reaction period the hvdrated phosphatides can be seeparated either by decantation (settling) or continuously by means of centrifuges.

In this process step a large part of hvdratable and even a small proportion of the non-hydratable phophatides are removed

The extracted gums can be processed into lecithin for food, feed or technical purposes.

The gum content in the ail is subsequenciy reduced according to the refining quality requirements.

in principle,the combination and concept of further processing stages in distinguished by

- chemical refining and

- physical refining

In chemical refining the free fatty acids are neutralized by caustic soda resulting so-called"soap stock"which is also seperated either

by decantation or continuously by means of centrifuges.

Simultaneously the non-hydratable phosphatides are also separated in this process.

In physical refining the gum content can be further reduced by different processes:

- Dry acid degumming or

- wet acid degumming.

Dry acid degumming

Dry acid degumming is particularly suitable for processing ails with law gum contents such as palm ail, coconut oil, palm kernel oil or animal fats. Intensive mixing is implemented following addition of acid to the pre-heated crude oil. The conditioned gums are absorbed into the bleaching earth and are separated by filtration.

The benefits of the dry acid degumming process are:

Efficiency as a result of

- low energy consumption.

- low operation and maintenance costs(sturdy and reliable control system),

- long service life(the components are acid proof],

- minimum footprint,

- low investment costs,

- environmental-friendly as no wastewater or soap stock occur.

wet acid degumiming

intially oils with higher gum contents (e.g corn oil) are similarly processed as in dry acid degumming.However, to achieve gum hydracion water is added following acid apportioning The gums are removed by a separation prior to bleaching. The process is beneficial as

- centrifuges enable easy separation of gums in oil types with higher non-hydratable gums contents (e.g rape oil and saybeen oil )

- The consumption of bleaching earth s reduced because the oil has allready been extensively degummed

Dry or wet acid degumming are not always sufficient to reduce gums to the value required in the oil prior to the combined deodorization and distillation process

Thus we have developed a special degummimg process

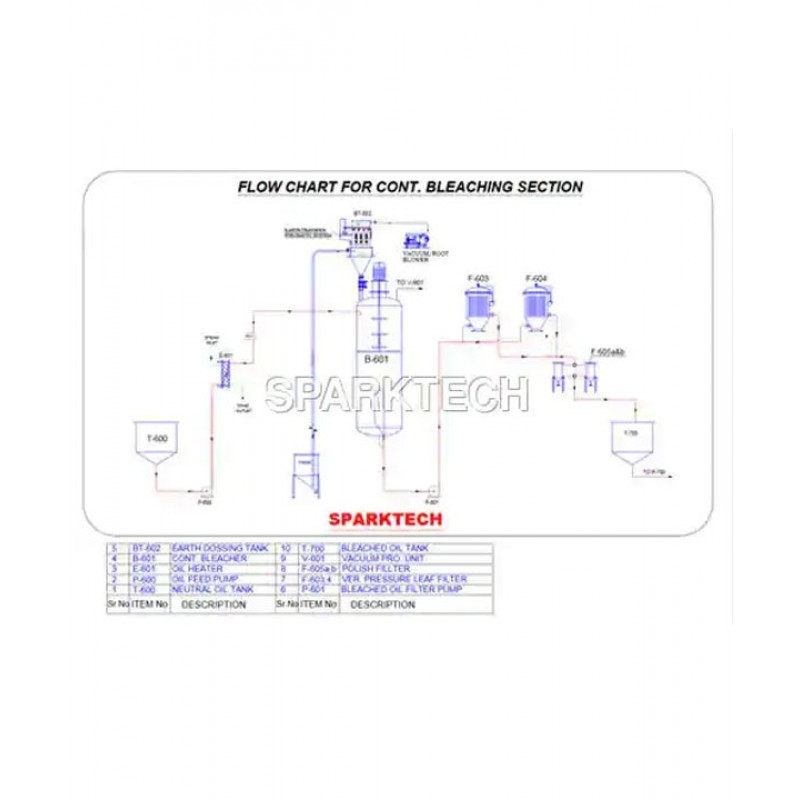

Bleaching

Today we use a continuous bleaching process apart from special applications and minor processing quantities

This is used for

- Bleaching degummed oil prior to physical neutralgation and deodorization,

- bleaching wet-degummed and chemically neutralized oil prior to deodorization,

- post-refining of hydrogenated and chemically interesterified oils and fats .

In this process a pre-defined quantity of bleaching earth (adsorbent natural or activated earth, mixed with activated carbon necessary) is continuously added to the oil

This process is specially characterized by the loop reactor enabling operation without the agitator tanks as well as simultaneous Intensive mixture and contact of the bleaching earth with the oil. The bleaching earth is filtrated following reaction period

In addition to the common target of lightening the oil color the bleaching process also meets numerous requirements:

The bleaching earth adsorbs color pigments as well as oxidation-supporting metal ions, complex compounds, residual soaps and similar substances such as traces of catalyst from hydrogenation.

Furthermore, it serves as a filter for impurities and for gums precipitated by acid in dry degumming.

The benefits of the continuous bleaching process are:

- Enhanced product quality, bleaching under vacuum, gentle heating through optimized temperature control, intensive discoloration of the oil,

- increased efficiency, optimized utilization of the bleaching earth through intensive reaction of the mixture during circulation in the loop reactor convenient operation and maintenance through sturdy flow and maintenance through sturdy flow and level control, easy filter emptying, degree of automation according to the customer's requirements, energy efficiency through additional heat recovery, higher wear resistance through high quality materials (eg. special pump seals)